NEWS

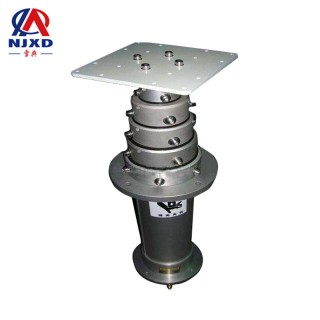

Pneumatic lifting rod cylinder classification and obturating ring type

Time:2020-10-19 View:

1. Classify whether the gas pressure borne by the pneumatic lifting rod/piston is one-way or two-way

(1) single-acting cylinder: the piston of the cylinder can only be driven by air pressure in one direction, and external force is required when reverse.

(2) double-acting cylinder: the piston of the cylinder is pushed by air pressure in both positive and negative directions.

2. Classification from the installation form of pneumatic lifting rod/cylinder

(1) fixed cylinder: the cylinder cylinder body is fixed.

(2) shaft pin cylinder: the cylinder cylinder body can swing around the fixed shaft pin in a certain angle.

(3) rotary cylinder: the cylinder cylinder body is usually fixed on the machine tool spindle and can rotate with the machine tool spindle. This kind of cylinder is usually used in pneumatic cartridge on the machine tool.

3. Classification from the functions and uses of pneumatic lifting rod/cylinder

(1) ordinary cylinder: including single-acting and double-acting cylinder. This type of cylinder is generally used without special requirements.

(2) buffer cylinder: the cylinder is equipped with a buffer device, which can avoid strong impact when the piston moves to the end. This type of cylinder is often used in working scenarios with high pressure and high movement speed.

(3) gas-liquid damping cylinder: the cylinder is connected with the hydraulic cylinder to obtain a more accurate movement speed. This kind of cylinder can be used in scenarios with high speed control requirements.

(4) swing cylinder: the movement of the cylinder is reciprocating rotation around axial lead, which can be used for mobile phone holder rotation, valve switch, etc.

(5) impact cylinder: it is a high-energy cylinder that forms an impact force with piston rod high-speed movement and can be used for stamping, cutting, etc.

Introduction to seal ring skills of several common pneumatic lifting rod (cylinder)

1.C2 type

(1) Application scale:

Used to prevent the sealing of rotating oval pneumatic lifting rod (cylinder).

Operating pressure: ≤ 160 bar * (hydraulic)

≤ 16 bar pneumatic)

Operating temperature: -25 ℃ to +100 ℃ (hydraulic)

-25 ℃ to +80 ℃ (pneumatic)

Appearance speed: ≤ 0.5MB/s

* Depends on the cross-section product and information.

Especially recommended for hydraulic cylinder and piston in pneumatic lifting rod (cylinder).

(2) Information:

Specification information N3584 is a nitrile rubber with 84A hardness.

For the conditions of high temperature and chemical-resistant media, we recommend the use of our company's fluorine rubber information. Low temperature application introduction N8613-80A.

2.E4

(1) primary strengths:

The shape of the sealing lip mouth of pneumatic lifting rod (cylinder) is planned to be able to operate in smooth oily air and dry oil-free air.

The structure is solid.

Tamp down cooperation is installed into the groove to ensure that the operation is secure.

The shape of the sealed lip can hold the initial smooth, so it has the best conflict characteristics.

Applicable to pneumatic lifting rod (cylinder) with buffer effect.

Good rubber composition is selected, so there is a longer working life.

Simply put it into a trench with a simple structure.

Joint Planning of sealing lips can ensure smooth operation during flow-controlled exhaust.

(2) application scale:

Used to prevent the sealing of rotating oval pneumatic lifting rod (cylinder).

Operating pressure: ≤ 10bar

Job temperature:

Standard information N3578: -30 ℃ to +80 ℃

Appearance speed: ≤ 1MB/s

Medium: oil-bearing Smooth Air, dry air and oil-free air (after the initial smooth of the device).

(3) information:

The specification information is a recognized component rubber (NBR base) with a hardness of about Shao 78A.

For various applications of high and low temperature, there are special information: V3664 and N8613.

3.MK type

(1) primary strengths:

The specially planned sealing lip structure has improved the sealing reliability of pneumatic lifting rod (cylinder) and reduced the conflict force together.

As a piston sealing element, mkcan be used together to supply different functions. Due to its structure shape, the difference between the MK is used to accept the primary radial force or for long-stroke piston

The decompression groove planning starting from the 32mm cylinder diameter achieves the best functional effect.

Integrated buffer planning with ventilation slot achieves optimal piston sealing effect.

Polyurethane information certified by many applications ensures a longer working life.

It is suitable for dry air or glossy and oily air together.

Asymmetric groove structure ensures that sealing element holds Force tight on the pneumatic lifting rod (cylinder) piston.

Concave-type persistence groove makes the device simpler.

Integrated Planning integrates seal, guide, and buffer functions on a component, reducing the number of parts.

The device space is reduced to the greatest extent.

(2) application scale:

Operating pressure: ≤ 12bar

Operating temperature: -30 ℃ to +80 ℃

Appearance speed: ≤ 1MB/s

Medium: dry oil-free air with glossy lubricating oil (after the device is smooth initially).

(3) information:

Specification information: P5010 polyurethane information (hardness about 90 Shore A)

Low temperature application: P5075 polyurethane information (hardness about 80 Shore A)

High temperature application: V3664 fluorine rubber information (hardness about 85Shore A)

4.OA type

(1) primary strengths:

For integral pneumatic lifting rod (cylinder) piston

Small device scale

Very small starting and moving conflict force, even at low speed can also ensure smooth movement, no crawling phenomenon

Wear resistant

Kneading resistance

High temperature resistance

(2) application scale:

Operating pressure: ≤ 16bar

Operating temperature: -30 ℃ to +80 ℃ *

Appearance speed: ≤ 4MB/s

(3) information:

Sliding ring: Polon? 033, modified PTFE + 25% carbon

O-ring: N0674, nitrile rubber with Shore hardness of about A 70

5.PZ type

(1) primary strengths:

The device has small groove and good sealing performance of pneumatic lifting rod (cylinder).

Because the shape of the sealing lip can save the light sub-controler to the greatest extent, the pneumatic lifting rod (cylinder) runs smoothly.

The structure is small, so static and dynamic conflicts are low.

Suitable for dry air and oil-free air. The initial smoothness of the device is crucial to the long working life.

It is easy to install into the sealed groove.

(2) application scale:

Operating pressure: ≤ 12 bar

Operating temperature: -20 ℃ to +80 ℃

Appearance speed: ≤ 1MB/s

Medium: oil-bearing Smooth Air, dry air and oil-free air (after the initial smooth of the device)

(3) information:

The specification information is NBR-based rubber information with a hardness of Shao's A71.

In high and low temperature situations, there are special information.

Low temperature: N8602,NBR (about 70 ShoreA)

High temperature: V8550,FKM (about 80 ShoreA)

6.Z5 type

(1) primary strengths:

There is no metal touch between the piston and pneumatic lifting rod (cylinder) cylinder, and then conflict prevention, especially between light metal and plastic rice container..

After optimizing the shape of the sealing lip, adhering to the smooth oil film, and selecting appropriate information, the operation is smooth.

Because when there is no dry air, it will supply a long service life after the initial smooth.

The same groove can also be used to seal Z7 with a single effect of pneumatic lifting rod (cylinder).

Easy device in integrated piston.

(2) application scale:

Operating pressure: ≤ 16 bar

Operating temperature: -30 ℃ to +80 ℃

Appearance speed: ≤ 1MB/s

Medium: smooth air and oil-free boring air after initial smooth.

(3) information:

Specification information: N3578, nitrile rubber, hardness is about Shao's 75A

Low temperature information: N8602, nitrile rubber, hardness is about Shao's 70A

High temperature information: V8550, fluorine rubber, hardness is about Shao's 80A

7.Z7 type

(1) primary strengths:

There is no metal touch between the piston and pneumatic lifting rod (cylinder) cylinder, and then prevent conflicts, especially for light metal and plastic rice container..

After optimizing the shape of the sealing lip, adhering to the smooth oil film, and selecting appropriate information, the operation is smooth.

Because when there is no dry air, it will supply a long service life after the initial smooth.

Z7 can also be used in the groove of Z5 double effect piston.

Easy device in integrated pneumatic lifting rod (cylinder) piston.

(2) application scale:

Operating pressure: ≤ 16 bar

Operating temperature: -30 ℃ to +80 ℃

Appearance speed: ≤ 1MB/s

Medium: smooth air and oil-free boring air after initial smooth.

(3) information:

Specification information: N3578, nitrile rubber, hardness is about Shao's 75A

Low temperature information: N8602, nitrile rubber, hardness is about Shao's 70A

High temperature information: V8550, fluorine rubber, hardness is about Shao's 80A

8.Z8 type

(1) primary strengths:

The device has small groove and good sealing performance of pneumatic lifting rod (cylinder).

Because it has a few shapes of the best sealing lips with smooth film and uses SFR to form rubber information that proves to be suitable on pneumatic equipment, it runs smoothly.

The cross section is small, so static and dynamic conflicts are low.

The joint planning of dynamic lips ensures that gas can be easily exhausted at low pressure.

Suitable for dry air and oil-free air. The initial smoothness of the device has the primary effect on the long working life.

The lip seal structure ensures that the sealing function is very reliable.

It is easy to install into the sealed groove.

It is also applicable to pneumatic lifting rod (cylinder) with buffer effect.

Polyurethane information is more wear-resistant and has longer longevity.

(2) application scale:

Operating pressure: ≤ 16 bar

Operating temperature: -20 ℃ to +80 ℃ N3580 (standard information)

-35 ℃ to +80 ℃ polyurethane P5007

Appearance speed: ≤ 1MB/s

Medium: oil-bearing smooth air and oil-free dry air after initial smooth.

(3) information:

Specification information: N3580, nitrile rubber, hardness is about Shao's A75.

Low temperature information: N8602, nitrile rubber, hardness is about Shao's A70.

High temperature information: V8550, fluorine rubber, hardness is about Shao's A80.

Specification information: P5007, polyurethane, hardness is about Shao's A82.

Low temperature information: P5075 polyurethane, hardness is about Shao's A80.

9.DE type

(1) primary strengths:

It can be briefly fixed on pneumatic lifting rod (cylinder) piston rod without any other sealing request.

Because the vent tank is constructed, it can respond quickly (full pressure load).

Because the shape of the sealing lip mouth of pneumatic lifting rod (cylinder) can hold the smooth film, the conflict is small and the operation is smooth.

It can be used for oil-bearing smooth air and dry oil-free air after initial smooth.

(2) application scale:

Operating pressure: ≤ 12 bar

Operating temperature: -30 ℃ to +80 ℃

Appearance speed: ≤ 1MB/s

Medium: oil-bearing smooth air and oil-free dry air after initial smooth.

(3) information:

Standard information is a kind of component rubber (NBR base) with hardness of Shao's A71 and vulcanized and bonded with metal the bones of the skeleton.

10.DK type

(1) primary strengths:

It can be briefly fixed on pneumatic lifting rod (cylinder) piston rod without any other sealing request.

All are coated with rubber and are not prone to corrosion.

Because the vent tank is constructed, it can respond quickly (full pressure load).

Because the shape of the sealing lip mouth of pneumatic lifting rod (cylinder) can hold the smooth film, the conflict is small and the operation is smooth.

It can be used for oil-bearing smooth air and dry oil-free air after initial smooth.

There is also a single effect of the same sealing scale pneumatic lifting rod (cylinder) piston seal EK available.

(2) application scale:

Operating pressure: ≤ 16 bar

Job temperature:

Standard information Z5051: -30 ℃ to +80 ℃

Standard information Z5071: -35 ℃ to +80 ℃

Appearance speed: ≤ 1MB/s

Medium: oil-bearing smooth air and oil-free dry air after initial smooth.

(3) information:

Standard information is a kind of component rubber (NBR base) with hardness of Shao's A71 and vulcanized and bonded with metal the bones of the skeleton.

When the cylinder diameter of pneumatic lifting rod (cylinder) is greater than 100mm, we recommend that you use information with hardness of Shao's 78A.

11.DP type

(1) primary strengths:

It can be briefly fixed on pneumatic lifting rod (cylinder) piston rod without any other sealing request.

Because a vent slot is provided, it can respond quickly (full pressure load).

Because the shape of the sealing lip mouth of pneumatic lifting rod (cylinder) can hold the smooth film, the conflict is small and the operation is smooth.

It can be used for oil-containing smooth air and oil-free air (after the initial smooth of the device).

(2) application scale:

Operating pressure: ≤ 12 bar

Job temperature: -30 ℃ to +80 ℃ (standard information)

Appearance speed: ≤ 1MB/s

Medium: oil-bearing Smooth Air, dry air and oil-free air (after the initial smooth of the device).

(3) information:

Standard information is a kind of component rubber (NBR base) with hardness of Shao's A71 and vulcanized and bonded with metal the bones of the skeleton.

12.EK

(1) primary strengths:

It can be briefly fixed on pneumatic lifting rod (cylinder) piston rod without additional sealing element.

All are coated with rubber and are not prone to corrosion.

Due to the planning of the vent tank, it can be quickly responded (full pressure load).

Because the shape of the sealing lip mouth of pneumatic lifting rod (cylinder) can hold the smooth film, the conflict is small and the operation is smooth.

It can be used for oil-bearing smooth air and oil-free air after initial smooth.

(2) application scale:

Integrated EK piston can be used for single effect pneumatic lifting rod (cylinder) with or without buffer at the end to prevent long travel and winding conditions and avoid receiving too large lateral loading.

Operating pressure: ≤ 16 bar

Job temperature:

Standard information Z5051: -30 ℃ to +80 ℃

Polyurethane Z5071: -35 ℃ to +80 ℃

Appearance speed: ≤ 1MB/s

Medium: oil-bearing smooth air and oil-free air after initial smooth.

(3) information:

The specification information is a nitrile rubber with a hardness of Shao's 71A and is bonded to the vulcanized the bones of the skeleton.

When the cylinder diameter of pneumatic lifting rod (cylinder) is greater than 100mm, we recommend that you use the information with hardness of Shao's 78A.

13.DR type

(1) Application scale:

Operating pressure: ≤ 10 bar

Operating temperature: -20 ℃ to +80 ℃(HNBR +120 ℃)

Appearance speed: ≤ 1MB/s

Medium: oil-containing Smooth Air, or dry oil-free air after initial smooth.

(2) Information:

Elastomer:

The specification information is nitrile rubber with Shore hardness A about 70 degrees, vulcanized on metal sheet and magnetic ring.

Magnetic ring:

The plastic the bones of the skeleton is hard ferromagnetism, axial magnetized.

Magnetic flux density:<41mT (depending on the nominal diameter of the air gap)

CATEGORY

NEWS

- Pneumatic lifting rod multi-section cylinder structure and comparison with hydraulic type

- Pneumatic lifting rod cylinder classification and obturating ring type

- Brief Analysis of working principle and technical comparison of pneumatic lifting platform

- Special Vehicle-mounted air compressor emergency communication vehicle for pneumatic lifting rod

- Selection and detailed introduction of pneumatic lifting bracket