NEWS

Lift Rod impact strength measurement experiment of materials

Time:2021-04-02 View:

Impact strength measurement experiment

Impact strength of simply supported beam and cantilever beam

The impact strength of simply supported beam and cantilever beam represent the energy absorbed per unit area of the material. The more absorbed, the better the impact resistance of the material. As shown in the figure on the right, there are two kinds of impact diagrams.

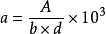

In these two experiments, the impact strength can be expressed by the following formula: , where a indicates the impact strength of simply supported beam or cantilever beam, unit: kJ/m2 (kilojoules per square meter);A represents the impact amount absorbed by the sample, Unit J; B represents the sample width, unit mm;d represents the sample thickness, unit mm. If it is notch impact, the thickness minus the remaining thickness after notch.

, where a indicates the impact strength of simply supported beam or cantilever beam, unit: kJ/m2 (kilojoules per square meter);A represents the impact amount absorbed by the sample, Unit J; B represents the sample width, unit mm;d represents the sample thickness, unit mm. If it is notch impact, the thickness minus the remaining thickness after notch.

From the calculation formula, we can know that the specifications (thickness, width, no gap, etc.) of the selected sample during the test will have an impact on the test results; If further discussed, the temperature during the test, the selected impact energy, impact velocity, span, etc. will all affect the test results; Theoretically, the larger the width and thickness of the sample used, the larger the impact energy A (unit: J) absorbed, however, the corresponding b×d (impact area) is also large (the relationship between impact area and impact energy is relatively complex, and there are many influencing factors, which are not linearly proportional), although the impact strength obtained in this way has deviation between different thickness, it will not be very large, and the impact strength of samples with thick thickness is not necessarily high (the impact strength only reflects the material itself, judging the impact resistance of A certain thickness of A material, we can compare the impact energy A absorbed by it).

At the same time, for rigid materials, under a certain degree of thickness and support span, there is structural elasticity, which has a great influence on the impact test results. Therefore, the national standard also stipulates: samples with a thickness less than 3mm generally do not conduct impact tests of simply supported beams or cantilever beams, and the upper limit of thickness is generally not more than 10mm; The test recommends the use of a thickness of 4mm. There is no clear regulation on the impact speed, span, thickness, etc. of the test, and only the proposal recommendation is provided.

To sum up, comparing the impact resistance of materials (simply supported beam and cantilever beam), only in the same time period, the same sample thickness, select the same test conditions (span, impact velocity, the same notch type, etc.) next, you can proceed. Moreover, because the influencing factors of material resistance to impact energy are very complex, the impact resistance reflected by simply supported beam or cantilever beam is only one-sided, so simply supported beam or cantilever beam are mostly used as auxiliary reference, judging the impact resistance of materials generally needs to be comprehensively determined by combining various testing items (elongation at break, elastic modulus, impact strength, etc.). For example, for some foamed materials with core layer, the data is extremely low when they are impacted by simply supported beams or cantilever beams, but the data when they are impacted by falling balls is not worse than that of similar materials.

Impact resistance test of falling ball or falling hammer

Falling ball impact and falling hammer impact reflect the impact resistance of the product itself (the impact resistance of a product is determined by many factors such as material, thickness, shape and structure). Place the sample on a certain size support span of a certain shape, and use a ball (or hammer) of a specific shape and weight to freely fall from a certain height to impact the sample, by changing the weight or falling height of the ball (or hammer), and a certain number of samples, the energy required for the sample to be destroyed can be determined qualitatively or quantitatively.

According to the national standard, we generally recommend that you select a circular span with a diameter of 75mm for the sample support span; Some row labels, landmarks, etc. also select some other required spans according to the actual use of the product, such as 50 × 500mm square support span, etc. Generally speaking, the span is also small. The greater the impact force under the same ball weight and height, the easier the sample is to be destroyed. The impact strength of falling ball (Hammer) is generally determined by whether the material is damaged or the quantity of damage under a certain test condition; The falling ball (hammer) when the sample is damaged can also be used. The gravitational potential energy is used to determine quantitatively. The test and calculation method can be carried out according to the standard.

The difference between falling ball and drop hammer lies in the shape of ball and hammer. The cross section of ball is round and the cross section of hammer is round and square. The impact strength of falling ball (Hammer) is also affected by the selected support span, sample thickness and sample shape. Under the same span and the same material, the impact strength of the falling ball (hammer) of samples with thick thickness is usually high; Under the same span, the same material and the same thickness, the falling ball (Hammer) is usually high. The impact point is that the sample of plane structure is easier to be damaged than the sample of special-shaped structure (it is related to force resolution during stress. Due to force resolution, the force on the cross section of the special-shaped sample is smaller).

Different impact tests of notched samples and non-notched samples

For the same material with the same shape, the impact strength of the spline notched sample is larger than that of the notched sample. The purpose of adopting the sample with notch is to greatly reduce the cross-sectional area of the sample at the notch. When impacted, the fracture of the sample must occur in this weak place, all the impact energy can be absorbed in this local place, called stress concentration, thus improving the accuracy of the test.