NEWS

Lift Rod precautions for wire rope

Time:2021-09-30 View:

Precautions

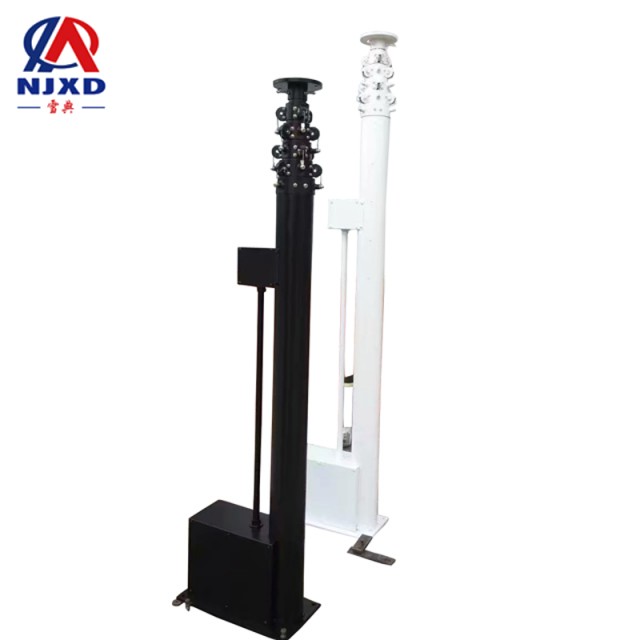

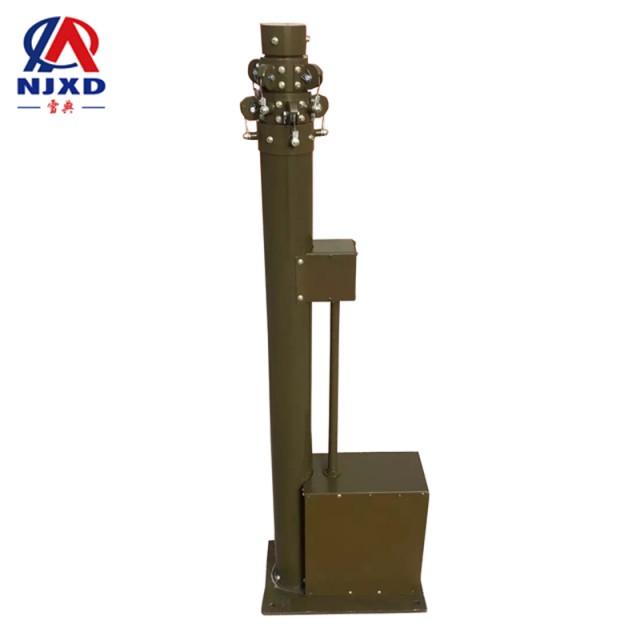

It can be used in telescopic mast.

(1) check before use

Inspection scope: check the degree of wear, corrosion, stretching, bending, deformation, fatigue, broken wire and rope core exposure of wire rope to determine its safe lifting

Quantity (including scrap).

(Ii) Maintenance precautions

(1) the service life of wire rope has a great relationship with the use method, so it should be used according to regulations, and dragging and pulling are prohibited,

Throwing, no overload during use, no sharp angle of wire rope folding, no sharp change of lifting speed, avoid impact

Load

(2) when the wire rope has rust and Ash scale, brush it with steel wire and apply oil

(3) the wire rope is oiled every 4 months. When oiling, it is best to soak the rope core with hot oil (about 50℃) and wipe it off

Excess grease

(4) after the steel wire rope plate is good, it should be placed in a clean and dry place, and it should not overlap and stack to prevent sprains.

(5) the end of the wire rope can be tightened with steel wire or welded with alloy with low melting point, or iron hoop can be tightened to avoid loose rope head

(6) in use, if oil droplets are squeezed out on the surface of the wire rope, it means that the wire rope has been subjected to considerable strength, and it should be stopped at this time.

Increase Load, check and replace new wire rope if necessary.

The bearing capacity of the Traction wire rope should be 5-8 times of the total traction force.

Elongation treatment

With the natural elongation of Traction wire rope, the force of each rope is different, and the tension deviation of each Traction wire rope (usually 4~7) will exceed 5% and exceed the difference.

As the running time of the newly installed elevator increases, the wire rope will naturally stretch. Theoretically, the elongation of Traction wire rope is about 0.5%. The impact on general low-rise elevators is not too great, but for high rise lift, especially 2:1 suspended elevators, the impact cannot be ignored. For example, for a passenger ladder on the l5 floor, the length of the Traction wire rope is about 50m. For example, if 2:1 is suspended, the length of the rope is about 100m, and the elongation of 0.5% is as much as 500mm. We know that the buffer distance of oil shock absorber is 200 ~ 350mm, and the buffer distance of spring buffer is 150 ~ 400mm. With the natural elongation of the Traction wire rope, the leveling accuracy will change. Some elevators can automatically re-flatten the layer, while most elevators need * maintenance workers to adjust the leveling accuracy, to make it meet the requirements of GBl0060-93 flat layer accuracy, in this way, the elongation of Traction wire rope is bound to stretch to the counterweight side, resulting in smaller and smaller buffer distance on the counterweight side, in the end, the buffer distance may be too small and too poor. In severe cases, even the counterweight in front of the flat floor of the elevator has been lifted to the buffer, resulting in elevator failure.

Handling comments:

① during installation, the buffer distance on the counterweight side should be as close as possible to the upper limit to make it bigger. Once the Traction wire rope is extended, you can make up for it yourself;

② during installation, the adjustment nut of Traction wire rope head plate should have an adjustment margin of about 100mm for maintenance workers to adjust;

③ 3 adjustment blocks should be added to the counterweight base (each adjustment block is about 120mm high). When the buffer distance changes, the maintenance worker can remove 1 to 3 adjustment blocks respectively according to the situation;

④ if there is no adjustment block for the counterweight base, and the rope head-plate adjustment nut cannot be adjusted, then we have to cut the wire rope again and redo rope head (you can change one by one without hanging the car, support counterweight).

Handling opinion: the maintenance worker measured the tension of each rope with spring scale at the height of 2/3 on the hoistway of the car, and adjusted the rope head plate nut so that the tension deviation did not exceed 5%.

Speed governor steel wire rope will naturally stretch under the action of the weight Hammer of the speed governor tensioning device. In severe cases, it will cause misoperation of the speed governor loose rope switch, making the elevator unable to operate.

Handling opinion: Re-bind the speed governor wire rope to make it meet the requirements, and restore the loose rope switch to the normal position.

With the natural elongation of Traction wire rope, Guizhou Guiyang elevator with compensation chain (rope) may cause compensation chain (rope) to mop the floor, causing unnecessary noise, and even compensation chain (rope) will be pulled out in severe cases. Support and other parts in damaged hoistway.

Handling opinion: maintenance workers should be diligent in inspection and find that compensation chain (rope) mopping floor should be re-tied to make it meet the requirements.

Relevant standards

Wire rope terminology

GB8706-88

This standard applies to wire rope products and common terms used in the standard. In the production (repair) of wire rope product standards and practical applications, the terms specified in this standard shall be adopted.

This standard is equivalent to the international standard ISO2532-74 wire rope-vocabulary.

In the wire rope, the steel wire and the strands of each layer are arranged in the form of minimum torque or minimum rotation degree, for example, in multiple layers, in the single-strand steel wire rope with the same structure, which forms a multi-strand steel wire rope and is twisted around an independent wire rope core, when the twisting direction of the steel wire and the strands of each layer is opposite, this kind of steel wire rope has lower torsional stress, thus, it presents non-rotation or micro-rotation.

1. Phosphate coated steel wire rope (Chinese patent), the phosphate film of the rope steel wire weighs 3-60g/square meter. After phosphating, the steel wire is directly twisted stranded rope, steel core and steel wire rope without cold drawing before twisting.

2. Galvanized steel wire rope, including Hot Galvanizing and electro galvanized two methods, the thicker the galvanized layer, the stronger the anti-corrosion ability.

3. Plastic coated wire ropes, coating plastic with a certain thickness on the outer surface of wire rope or stranded rope, including polyethylene, polypropylene, polyurethane, etc.

4. Smooth steel wire rope, rope-making steel wire obtained after heat treatment and cold drawing of raw materials prepared on the surface (note: The phosphating film formed in the pretreatment process gradually falls off with the drawing die during cold drawing), steel wire is no longer directly twisted stranded rope, steel core and steel wire rope through any surface treatment. It began to be produced abroad in 1834 and Tianjin No. 1 steel wire rope factory in China in 1939.