NEWS

Technical requirements for lifting lightning protection devices

Time:2021-01-06 View:

1 Overview

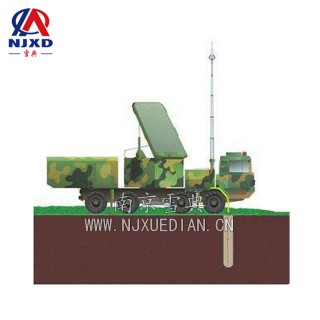

This paper puts forward the technical agreement of X-car lightning protection device as the basis for the development of X-car lightning protection device. The lightning protection device of X vehicle is mainly used for the protection ability of lightning in the status and reprint of X vehicle.

2 Scope of Application

This technical agreement is applicable to the lightning protection device design for lightning protection in X vehicle travel Army state and reprint state.

3 Main composition, function and technical index requirements

3.1 Composition

Lightning protection device is mainly composed of insulation jacket, insulation inner sleeve, induction-free winding, Lightning receiver, down lead plug, etc.

3.2 Functions

The lightning protection device mainly completes the lightning protection function for X vehicle travel Army status and reprint status, and has the automatic scaling capability.

3.3 Technical index requirements

(1) dimensions

Folded length: ≤ 2000mm;

expanded length :≥14000m 。

(2) Weight: ≤ 50kg;

(3) protection level: IP65 (ip67below 1000mm wading line);

(4) Power: ≤ 1kw;

(5) Electricity Consumption: 24VDC;

(6) life: the number of scaling cycles is not less than 20000 times;

(7) lightning protection radius is calculated according to GB50057-2010 grounder method.

3.4 Use environment

3.4.1 temperature

a) Operating temperature:-35℃ ~ + 45℃;

B) storage temperature:-45℃ ~ + 60℃.

3.4.2 humidity

The relative humidity is not more than 98%(30℃).

3.4.3 sunshine

Maximum 1120w/m 2±112w/m2, Duration 4H.

3.4.4 rainfall

Under moderate rain (2.6mm/h ~ 8mm/h), the lightning protection device should work normally. Under the rain condition with the rainfall intensity of 6 mm/min, place the lightning protection device for 30min. The internal protection should not leak water. After the rain, the insulation resistance of the lightning protection device meets the requirements of special technical conditions.

3.4.5 plateau adaptability

The altitude is 5500m and has the ability to work normally.

3.4.6 salt spray

When used and stored in coastal waters, islands and other salt spray environments, the protective layer of parts exposed to the air should have good salt spray resistance. The test piece has a temperature of 35℃, the corrosion resistance of 5% saline solution spray should meet the requirements of GJB150.11A-2009.

3.4.7 mold

The protective layer of selected components, wires and cables, standard parts, purchased parts and self-made parts should have good anti-mold ability, and the test pieces should meet the secondary requirements of GJB150.10A-2009.

3.4.8 sand dust

When working in sand and dust environment, it should meet the requirements of GJB150.12A-2009, and the extreme value of sand and dust concentration is 1g/m3.

3.4.9 vibration

In the folded state, the standard of gj168.0.16 A- 2009 is met.

3.4.10 wind load

Under the deployment state of lightning protection device, the average wind speed against the ground is ≥ 15 m/s; The instantaneous average wind speed is 22.5 m/s.

3.5 Interface Requirements

a) mechanical interface

Interface adaptation with car chassis (interface schematic diagram to be supplemented)

B) electrical interface

The electrical interface of lightning protection device is shown in Table 1.

Table 1 Electrical interface of lightning protection device

Terminal Number

Terminal mark

Signal name

Function

1

DC24V+

Power +

Power supply

2

DC24V-

Power supply-

3.6 Other requirements

3.6.1 reliability

a) qualitative requirements

The lightning protection device should reasonably set control strategies, simplify the complexity of the equipment, preferentially adopt mature technology, optimize the operation process, fully consider the man-machine adaptability when designing the product, and avoid human operation errors, improve people's reliability of service of products.

B) quantitative requirements

(1) Average fault interval: ≥ 2000H;

(2) service life: ≥ 25 years.

3.6.2 maintainability

a) qualitative requirements

(1) simplify product and maintenance operations;

(2) each module and parts of the equipment should adopt good accessibility technology to make it have good accessibility;

(3) equipment layout and installation location should be convenient for maintenance personnel to approach the maintenance object and carry out maintenance operations;

(4) in the design, the standard components, parts, equipment and tools are preferred, and the variety and specifications is minimized;

(5) adopt modular design to compress the number of modules to Improve interchangeability during maintenance;

(6) perfect anti-misinsertion design and identification mark;

(7) the arrangement of cable pipelines should avoid pipeline crossing and confusion.

B) quantitative requirements

(1) Average repair time at the base level: ≤ 30min;

(2) maximum repair time at the base level: ≤ 60min.

3.6.3 security

The design of lightning protection device should have protection functions such as over-current and over-voltage, and the electrical part should have anti-insertion wrong design. Ergonomic design is considered in the design to ensure the safety of personnel operation.

3.6.4 supportability

Adopt universal and modular design to simplify the complexity of equipment and the number of modules as much as possible, minimize the types and specifications of parts, avoid short-life parts as much as possible in system design and selection, and reduce maintenance guarantee requirements.

The equipment of maintenance spare parts, testing equipment, repairmen and documents shall meet the requirements of routine maintenance, minor repair and medium repair of the Army.

3.6.5 testability

a) qualitative requirements

(1) with self-diagnosis function, and fault location to a single module;

(2) design test interfaces and provide access interfaces without testing and maintenance;

(3) necessary checkpoints should be left in the design process;

(4) testpoint should have adaptive protective measures to avoid being affected by the environment or external signals;

(5) the man-machine operation interface is friendly, and it should have the functions of Operation error alarm, prompt and self-locking to reduce equipment loss caused by Operation error 2.

B) quantitative requirements

(1) system fault detection rate (replaceable unit can be detected):≥ 0.96;

(2) system fault isolation rate (ambiguity 2):≥ 0.98;

(3) false alarm rate: ≤ 0.05.

3.6.6 Electromagnetic compatibility

It meets the following 7 index requirements in GJB151B-2013 requirements for electromagnetic emission and sensitivity of military equipment and sub-systems, meets GJB1389A-2005 requirements for system electromagnetic compatibility, and can work in normal coordination with the system.

a)CE102 10kHz ~ 10MHz power line conduction emission;

B) CS101 25Hz ~ 150kHz power line conduction sensitivity;

c)CS114 4kHz ~ 400MHz cable beam injection conduction sensitivity;

d)CS115 cable beam injection pulse excitation conduction sensitivity;

e)CS116 10kHz ~ 100MHz cable and power line damping sinusoidal instantaneous conduction sensitivity;

f)RE102 10kHz ~ 18GHz electric field radiation emission;

g)RS103 10kHz ~ 40GHz electric field radiation sensitivity.

3.6.7 component selection

Before installation, electrical components must undergo visual inspection and functional inspection. Components that have not been screened and qualified shall not be installed. The specification and quantity control ratio of electrical components used shall not exceed 5%, among which Purple, the combination of orange and yellow imported components shall not exceed 2%, and the use of imported components shall be strictly examined and controlled.

CATEGORY

NEWS

- The future development direction of mobile communication

- Technical requirements for lifting lightning protection devices

- Development History of 3G mobile communication technology

- The development history of 4G5G lifting mobile communication technology

- Cluster system and satellite communication lifting mobile communication system