NEWS

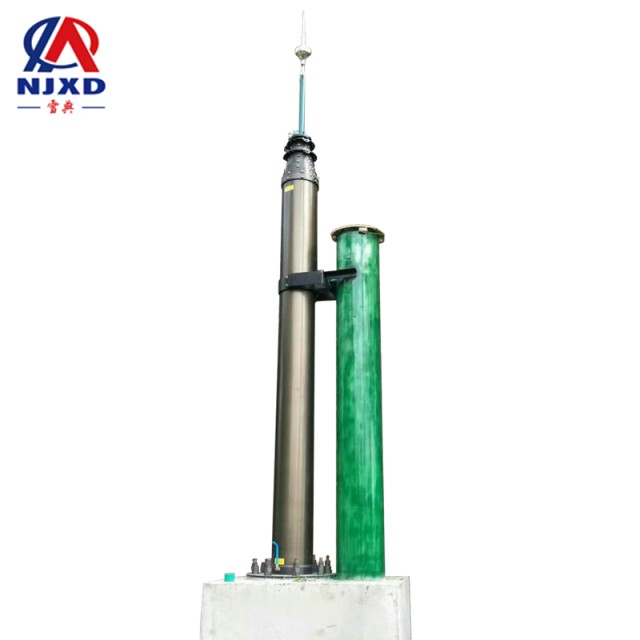

Components of lightning protection device ightning Rod telescopic mast

Time:2021-05-07 View:

Flash receiver

Lightning receiver is a metal object specially used to accept thunder flash. The flashing metal rod is called Lightning arrester, the flashing metal wire is called ground wire or overhead earth wire, and the flashing metal strip and a wire fence are called Lightning strip or lightning conduction. All lightning receivers must be connected to the grounding device through down lead.

Ightning Rod, ground wire, Lightning conduction, and lightning strip are both lightning receivers, which take advantage of their prominent position of being preserver higher than that of being, lead the Lightning to itself, and then discharge the lightning current into the earth through down lead and grounding device, to protect preserver from lightning strikes. The materials used in the Lightning receiver should meet the requirements of mechanical strength and corrosion resistance, and should also have sufficient thermal stability to withstand the thermal damage of lightning current.

(1) ightning Rod

Ightning rod is generally made of galvanized round steel or galvanized welded steel pipe. It is usually installed on the frame, pillar or building, and its lower end is welded with grounding device through down lead. Because ightning rod is higher than preserver and is directly connected to the Earth, when Lei Yun is close to the pilot, the electric field strength between it and Lei Yun is the largest, therefore, the lightning discharge path can be attracted to the ightning rod itself and the lightning current can be safely released to the Earth through the down lead and grounding device, so that the preserver body can be protected from direct lightning strike.

The protection range of ightning rod is expressed in the space where it can protect against direct thunder. The scope of lightning conductor protection is calculated according to the method specified in GB50057-1994 code for lightning protection design of buildings.

(2) ground wire

Ground wire is erected on the top of overhead lines to protect overhead lines or other objects (including buildings) from direct lightning strikes. Ground wire is also called overhead earth wire because it is both overhead and grounded. The principle and function of ground wire are basically the same as that of ightning rod, and its protection scope is calculated according to the method specified in GB50057-2000 code for lightning protection design of buildings.

(3) lightning belt and lightning conduction

Lightning belts and lightning conduction are commonly used to protect higher buildings from lightning strikes. Lightning belts are generally installed around the roof, 100mm ~ 150mm above the roof, and the distance between supporting cards is 1m ~ 1.5m. Lightning conduction in addition to the installation around the roof, when necessary, the roof is also connected with round steel or flat steel vertically and horizontally to form a net. Lightning strip and lightning conduction must be reliably connected to grounding device through down lead.

down lead

The down lead of lightning protection device should meet the requirements of mechanical strength, corrosion resistance and thermal stability.

Arrester

Lightning arrester is connected in parallel to protected equipment or facilities, and the normal fashion is set to insulation against ground. When lightning overvoltage occurs, the device changes from insulation to conduction with the ground, and breakdown and discharge, introducing lightning current or overvoltage into the earth plays a protective role. After the overvoltage is terminated, the arrester quickly returns to the unreachable state and returns to normal operation. Lightning arrester is mainly used to protect power equipment and power lines, and is also used as a safety measure to prevent high voltage from intruding into the room. Lightning arrester has protection gap, tube type lightning arrester, valve type lightning arrester and zinc oxide lightning arrester.

Lightning arrester is a kind of overvoltage protection equipment, which is used to prevent atmospheric overvoltage generated by lightning from intruding into substation or other buildings along overhead lines. Lightning arrester can also limit internal overvoltage. Lightning arrester is generally connected in parallel with the protected equipment and is located on the power supply side. Its discharge voltage is lower than the insulation withstand voltage value of the protected equipment. When overvoltage intrudes along the line, the arrester will first break down and discharge to the ground, thus protecting the following equipment.

(1) valve arrester

Valve arrester consists of spark gap and valve plate in series and is installed in sealed porcelain casing. The spark gap is made of copper sheet. Under normal circumstances, the spark gap can prevent the power frequency current on the line from passing through. Under the action of lightning overvoltage, the spark gap is broken down and discharged. Valve plate is composed of binding electrical particles silicon carbide with ceramic materials, which has nonlinear characteristics. When the voltage is normal, the valve plate resistance is very large; When the voltage is over, the valve plate resistance is very small. Therefore, when over-voltage occurs on the line, the spark gap is broken down, and the lightning current can be smoothly released to the Earth valve plate. When the overvoltage disappears and the power frequency voltage is restored on the line, valve plate presents a large resistance, which makes the spark gap insulation recover quickly and cut off the power frequency freewheeling, thus protecting the line to resume normal operation. It should be noted that when lightning current flows through valve plate resistor, voltage drop is formed, which is the residual overvoltage, called residual voltage. Residual pressure should be added to the protected equipment, so residual pressure cannot exceed the allowable withstand voltage value of equipment insulation, otherwise it may breakdown the equipment insulation. This lightning arrester is generally used in transformer and distribution offices.

(2) exhausting arrester

Exhausting arrester is also called tubular arrester, which consists of three parts: production pipe, internal gap and external gap.

When overvoltage occurs in the line, both the external gap and the internal gap are broken down to drain the lightning current into the earth. The following power frequency freewheeling (whenever the gap is broken down by lightning overvoltage, current will continue to pass through the ionized gap under the action of power frequency voltage, which is called power frequency freewheeling) ARC is also generated in the pipe, which generates high-pressure gas in the gas pipe and ejects it from the annular pipe mouth. Arc blowing is strong. When the current passes zero for the first time, arc extinguishing is possible. At this time, the air in the external gap restored insulation, which isolated the arrester from the power system and resumed normal operation.

Exhausting lightning arrester has the outstanding advantage of small residual pressure, which is simple and economical, but gas is discharged when acting, so it is generally only used for outdoor lines.

(3) metal oxide arrester

Metal oxide arrester is also called zinc oxide arrester. It is composed of varistor sheet and has excellent Valve characteristics. Under the power frequency voltage, it presents great resistance, which can quickly and effectively block the power frequency freewheeling; Under the overvoltage, the resistance is very small, can drain lightning current well. Metal oxide arrester also has the advantages of small volume, light weight, simple structure, low residual pressure, fast response, etc.