NEWS

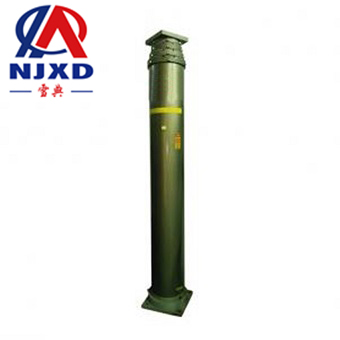

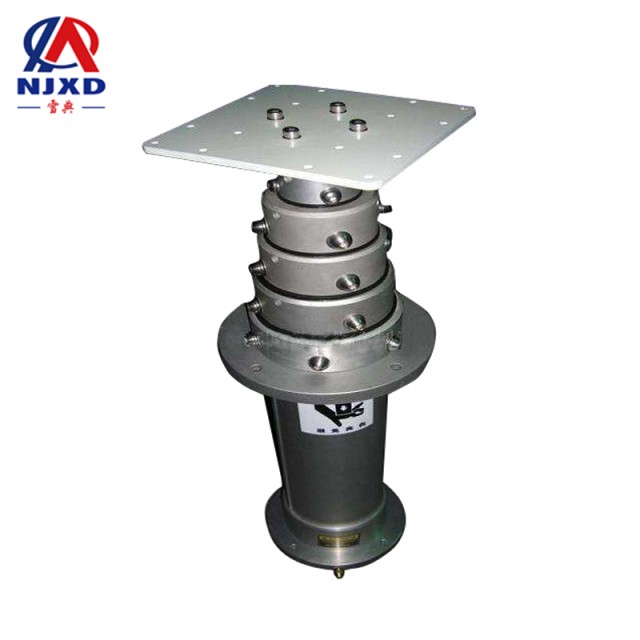

Roller structure rotatable lift rod

Time:2021-08-19 View:

The rotatable lift rod has two rotating modes, namely manual roller type and electric motor type.

Roller full name rolling bearing, the function is to support the rotating shaft and the parts on the shaft, and maintain the normal working position and rotation precision of the shaft. The rolling bearing is convenient to use and maintain, reliable to work, good starting performance, high bearing capacity at medium speed. Compared with sliding bearings, rolling bearings have larger radial dimensions, poor damping capacity, low service life at high speed and loud sound.

Introduction

Rolling Bearing (rollingbearing) is a precise mechanical component that changes the sliding friction between the running shaft and shaft seat to rolling resistance, thus reducing friction loss. Rolling bearings generally consist of four parts: inner ring, outer ring, rolling body and Holder. The function of the inner ring is to match with the shaft and rotate with the shaft; The function of the outer ring is to cooperate with the bearing seat and play a supporting role; the rolling body distributes the rolling body evenly between the inner ring and the outer ring by means of Holder. Its shape, size and quantity directly affect the service performance and service life of the rolling bearing; Holder can make the rolling body evenly distributed, guide the rolling body to rotate and play a lubricating role.

Function

Support the rotating shaft and the parts on the shaft, and maintain the normal working position and rotation precision of the shaft. The rolling bearing is convenient to use and maintain, reliable to work, and has good starting performance, high bearing capacity at medium speed. Compared with sliding bearings, rolling bearings have larger radial dimensions, poor damping capacity, low service life at high speed and loud sound.

Structure

The structure of rolling bearing consists of parts

1. Outer ring-installed in the bearing seat hole, generally not rotating

2. Inner ring-mounted on the journal, rotating with the shaft

3. Rolling body-core components of rolling bearing

4. Holder -- evenly separate the rolling bodies to avoid friction

Lubricant is also considered as the fifth largest part of rolling bearing, which mainly plays the role of lubrication, cooling, cleaning, etc.

Features

1. Specialization

In the processing of bearing parts, bearing special equipment is widely used. For example, steel ball processing adopts ball grinding machine, grinding machine and other equipment. The characteristics of specialization are also reflected in the production of bearing parts, such as steel ball companies specializing in the production of steel balls, micro bearing factories specializing in the production of miniature bearings, etc.

2. Advanced

Due to the large scale requirements of bearing production, it is possible to use advanced machine tools, tooling and technology. Such as CNC machine tools, three-jaw floating Chuck and heat treatment of protective atmosphere, etc.

3. Automation

The specialization of bearing production provides conditions for its production automation. Fully automatic, semi-automatic special and non-special machine tools are widely used in production, and automatic production lines are gradually popularized and applied. Such as heat treatment automatic line and assembly automatic line, etc.

Basic features

Advantages

1. Low friction resistance, low power consumption, high mechanical efficiency and easy starting;

2. Standardized size, interchangeability, easy installation and disassembly, and convenient maintenance;

3. Compact structure, light weight and smaller axial size;

4. High precision, large load, small wear and long service life;

5. Some bearings have automatic centering performance;

6, suitable for mass production, stable and reliable quality, high production efficiency;

7. The friction torque of transmission is much lower than that of fluid dynamic pressure bearing, so the friction temperature rise and power consumption are lower;

8. The starting friction torque is only slightly higher than the rotating friction torque;

9. The sensitivity of bearing deformation to load change is less than that of fluid dynamic pressure bearing;

10. Only a small amount of lubricant is needed to operate normally, and lubricant can be provided for a long time during operation;

11. Axial dimension is smaller than traditional fluid dynamic pressure bearing;

12. Can bear the combined load of radial and thrust at the same time;

13. In a large load-speed range, the unique design can obtain excellent performance;

14. Bearing performance is relatively insensitive to the fluctuation of load, speed and running speed.

Disadvantages

1. Loud noise.

2. The structure of the bearing seat is relatively complex.

3. High cost.

4. Even if the bearings are well lubricated, installed correctly, dustproof and moisture-proof tightly, and run normally, they will eventually fail due to the fatigue of the rolling contact surface.

Performance

Centering performance

When the axis center line is inclined relative to the center line of the bearing seat hole, the bearing can still work normally. Double-row radial spherical ball bearing and double-row radial spherical roller bearing have good centering performance. Roller bearings and needle roller are not allowed to have relative inclination between the inner and outer ring axes. The allowable inclination angles of all kinds of rolling bearings are different. For example, single row radial ball bearings are 8 '~ 16', double row radial ball surface ball bearings are 2 ° ~ 3 °, and tapered roller bearing ≤ 2 ′.

The limit speed is highest revolving speed allowed by the bearing under certain load and lubrication conditions. The limit speed is related to bearing type, size, precision, clearance, Holder, load and cooling conditions. Bearing working speed should be lower than the limit speed. Selecting high-precision bearings, improving the structure and materials of Holder, adopting fog lubrication, improving the cooling conditions, etc. can all increase the limit speed.

Bearing lubrication

There are mainly grease lubrication and oil lubrication. Grease lubrication is not easy to leak, easy to seal, long service time, easy maintenance and high oil film strength, but the friction torque is larger than oil lubrication, so it is not suitable for high speed. The loading amount of grease in the bearing should not exceed 1/2~1/3 of the bearing space, otherwise the bearing will be overheated due to too much stirring lubricant. The cooling effect of oil lubrication is good, but the sealing and oil supply device is more complicated. The viscosity of the oil is generally 0.12-0.2cm/second. When the load is large, the oil with high viscosity should be selected when the working temperature is high, and the oil with low viscosity should be selected when the rotating speed is high. Lubrication methods include oil bath lubrication, drop lubrication, fog lubrication, oil injection lubrication and pressure oil supply lubrication. During oil bath lubrication, the oil surface should not be higher than the bottom rolling body Center. If the bearing is designed according to the elastic fluid dynamic pressure lubrication theory and the lubricant viscosity is selected, the contact surface will be separated by the oil film. At this time, under the action of stable load, the bearing life can be increased many times.

Modern machines, instruments and other equipment are developing towards high speed, heavy load, precision, lightness and other aspects, which puts forward many new requirements for rolling bearings, for example, when the size is reduced, the bearing is required to maintain or even increase the rated load, and new technologies are adopted to improve the process to improve the manufacturing accuracy and reduce the cost. Universal Rolling bearings have been difficult to meet all kinds of requirements. Special bearings should be designed and manufactured for machinery and equipment with large production volume. While strengthening standardization, varieties should be increased and the proportion of special bearings should be expanded. The development of modern industry also needs special bearings working under special working conditions, such as bearings working in high speed, high temperature, low temperature, strong magnetic field or in acid, alkali and other media.

Advantages

(1). Energy saving is remarkable. Due to the characteristics of rolling bearing's own motion, its friction force is much smaller than that of sliding bearing, which can reduce the power consumption consumed in friction resistance, so the energy saving effect is remarkable. From the theoretical analysis and production practice, main bearing the general small ball mill with rolling bearings can save electricity by 30%~ 35%, Medium Ball mill can save electricity by 15%~ 20%, and large ball mill can save electricity by 10%~ 20%. Since the ball mill itself is a large energy consumer in production, it will mean that it can save a sum of its considerable cost.

(2) convenient maintenance and reliable quality. Rolling bearings can save a series of complex maintenance processes with high technical requirements, such as melting, casting and tile scraping of Babbitt alloy materials, as well as oil supply and water supply cooling systems, so the maintenance volume is greatly reduced. Moreover, the quality of rolling bearings is often guaranteed because they are manufactured by professional manufacturers. It also brings convenience to ball mill manufacturers.

Select

There are various types of rolling bearings, and the following factors can be considered when selecting them.

a. Load size, direction and properties

Ball bearings are suitable for bearing light loads, and roller bearings are suitable for bearing heavy loads and impact loads. When the rolling shaft bears pure axial load, thrust bearing is generally selected; When the rolling shaft bears pure radial load, deep groove ball bearing or short cylindrical roller bearing is generally selected; When the rolling shaft bears pure radial load, when there is still a small axial load, deep groove ball bearing, angular contact ball bearing, tapered roller bearing and self-aligning ball or self-aligning roller bearing can be selected. When the axial load is large, angular contact ball bearings and tapered roller bearings with large contact angle can be selected, or radial bearings and thrust bearings can be combined together, which is especially suitable when extremely high axial load or special requirements are larger than axial stiffness.

Rolling Bearing

Together.

B. Allowable speed

There are great differences due to different types of bearings. In general, bearings with low friction and less calorific value are suitable for high rotation speed. The design should strive to work under the condition that the rolling bearing is lower than its limit speed.

c. Rigidity

When the bearing bears the load, elastic deformation will occur at the contact between the bearing ferrule and the rolling body. The deformation is proportional to the load, and its ratio determines the rigidity of the bearing. Generally, the rigidity of the bearing can be improved by pre-tightening of the bearing. In addition, considering the combination and arrangement of bearings in the bearing support design can also improve the bearing stiffness.

d. Centering performance and installation error

After the bearing is loaded into the working position, the installation and positioning are often caused by manufacturing errors. At this time, the bearing is often subjected to excessive load due to reasons such as fishing degree and thermal expansion of the shaft, resulting in early damage. Automatic self-aligning bearing can overcome the defects caused by installation errors by itself, so it is a bearing suitable for such purposes.

e. Installation and removal

Tapered roller bearing, needle roller bearing, etc., belong to the type of inner and outer ring separable bearing (the so-called separated bearing), easy to install and disassemble.

f. Marketability

Even bearings listed in the product catalog may not be sold in the market; On the contrary, some bearings not listed in the product catalog are produced in large quantities. Therefore, it should be clear whether the bearings used are readily available.

CATEGORY

NEWS

- Wind energy density grade telescopic mast wind resistance and wind power generation

- Roller structure rotatable lift rod

- Emergency Command Car System vehicle lifting bracket

- Introduction of vehicle-mounted lifting antenna for emergency communication vehicle

- Principle and composition of xenon lamp lighting lifting bracket