NEWS

Comparison between Pneumatic lifting bracket and hydraulic lifting bracket

Time:2020-07-21 View:

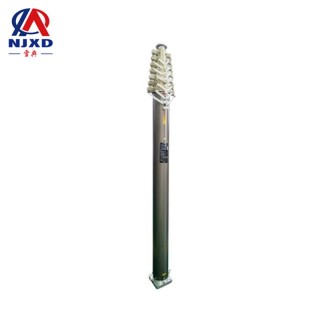

Xuedian NJXD pneumatic lifting bracket:

The air compressor of the NJXD pneumatic lifting rod is installed in the control box, and the control box can be placed in a suitable position on the ground. There are only pneumatic pistons in the Rod of the pneumatic lifting rod, without strong electricity or motor, and, the working voltage is safe 12V and 24V, so it is very safe and reliable to use! PYF pneumatic lifting rod can work normally, reliably and safely even if it is completely soaked in water for a long time.

Xuedian NJXD hydraulic lifting bracket:

The hydraulic pump and motor are configured in the lifting rod and are directly powered by 220V voltage! Because the hydraulic lifting rod body is buried under the ground, there is the possibility of water inflow, which not only has a great impact on the safety and reliability of the product, but also has great danger to pedestrians and maintenance personnel.

Xuedian NJXD pneumatic lifting bracket:

If the pneumatic system leaks air, the compressor will automatically pressurize and the equipment can continue to work normally within a reasonable time. Moreover, air leakage of pneumatic lifting rod has no cost, no environmental pollution and no maintenance cost.

Xuedian NJXD hydraulic lifting bracket:

Such as oil leakage in the hydraulic system, hydraulic pump failure and so on, the whole hydraulic system needs to be replaced, which is time-consuming, laborious and costly. Oil leakage not only pollutes the environment, but also causes the system to fail to work normally.

Xuedian NJXD pneumatic lifting bracket:

The pneumatic lifting rod part adopts the overall design, and the rod part can consider more anti-impact design, so the anti-impact capability is strong, and the reinforced cylinder has strong anti-impact capability, after the impact, the equipment can still operate normally, which has a real anti-terrorism meaning. There is only a low-cost pneumatic piston inside the pneumatic lifting rod. Even if it is accidentally hit, it will cause damage to the rod body and internal piston, and the maintenance cost is very low and very simple. The rising and falling of pneumatic lifting rod are all driven by compressed air, which runs fast and can be used at high frequency.

Xuedian NJXD hydraulic lifting bracket:

The plastic slide frame is used, which means that it has almost no impact resistance. A little collision requires repair, and the maintenance cost is very high! At the same time, the lifting rod is directly fixed on the central shaft of the hydraulic cylinder without any damping measures. In case of collision, the hydraulic cylinder is easy to be destroyed, resulting in oil leakage, resulting in a decrease in the running speed of the equipment or failure to operate. The hydraulic cylinder has high requirements, needs special customization, and has high cost. When the rod body is accidentally hit, the hydraulic motor integrated in the rod body is extremely vulnerable to damage, and maintenance is time-consuming and cost-effective.

Xuedian NJXD pneumatic lifting bracket:

The use and maintenance of pneumatic system are clean and convenient without any pollution to the environment. Due to the adoption of compressed air and fast connector, the installation personnel only need to make simple preparation to put into work, and the requirements for maintenance personnel are not high. There is no need to do cleaning work. At the same time, due to the use of hoses, the pipes are very convenient! If the gas pipeline is damaged, the replacement is convenient and cheap.

Xuedian NJXD hydraulic lifting bracket:

The hydraulic lifting rod uses dirty hydraulic oil that may pollute the environment (there is often leakage of hydraulic oil). Due to the complex structure of the hydraulic system, the internal maintenance space is relatively small, and the technical requirements for installation and maintenance personnel are relatively high. The cleaning and maintenance work of the system is also very demanding, the application environment is very demanding, and the maintenance work needs to be done frequently, otherwise, the running speed will be reduced or the operation of the equipment will be difficult; At the same time, the oil supply copper pipe is thick and hard, and the layout is very inconvenient!

CATEGORY

NEWS

- Emergency trailer lift bracket with customizable trailer length

- Comparison between Pneumatic lifting bracket and hydraulic lifting bracket

- Classification mode of pneumatic lifting bracket and special oil for air compressor

- Working Principle of oil-gas separator of air compressor with pneumatic lifting bracket

- Analysis on the operating principle and advantages of Xuedian pneumatic lifting rod