NEWS

Lift Rod stress hazards of materials

Time:2021-04-13 View:

Harm

Cracking

Due to the existence of stress, it will induce stress release and crack at the residual stress position after being affected by external effects (for example, when it comes into contact with chemical solvent during pad printing or highbake at the back end of paint). Cracking is mainly concentrated at the gate or overfilled place.

Warpage and deformation

Because of the existence of residual stress, the product will release the internal stress for a long time at room temperature or the process of releasing the residual stress for a short time at high temperature. At the same time, the product has local position strength difference, the product will cause warping or deformation problems at the residual stress position.

Product Size change

Because of the existence of stress, after the product is placed or processed, if the environment reaches a certain temperature, the product will change due to stress release.

Residual stress relief

Natural aging relaxation of residual stress

Natural aging is a method to stabilize the dimensional accuracy of parts by exposing them to the outside for several months to several years. A large number of experimental studies and production practices have proved that natural aging has a good effect of stabilizing the dimensional accuracy of castings.

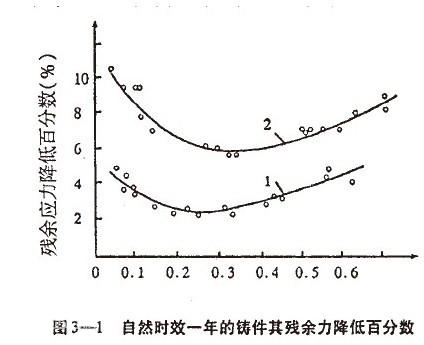

However, the change of residual stress of the workpiece after natural aging is not obvious. As can be seen from Figure 3-1, after the casting sample is placed for one year, the residual stress only decreases by 2-10%; the results of measured machine body residual stress show that after one year of natural aging, the maximum residual stress decreases from 80N/mm to 70N/mm and the average residual stress decreases from 38N/mm to 30N/mm, that is, only about 10-20% is reduced. Thus, the castings that have stopped deformation after natural aging still have considerable residual stress. For those castings that need to bear a large load during use, when the applied stress is superimposed on the higher residual stress, the service performance of the castings may be affected, therefore, we must carefully consider whether this aging method should be adopted.

Thermal aging method

The most traditional and popular method-thermal aging method, put the workpiece into the thermal aging furnace for heat treatment, and slowly eliminate stress. The disadvantages of this method are also very obvious. For example, aluminum alloy workpieces with very strict temperature control requirements and giant workpieces with a length of 10 meters or more cannot be handled by this method. Moreover, this method also brings a lot of pollution and energy consumption. With the further requirements of environmental protection in China and the world, the treatment method of hot aging furnace is facing a situation of full withdrawal immediately.

Use subresonance to eliminate stress

Although this method solves the environmental protection problem of thermal aging, it is quite cumbersome to use. It is necessary to compile different aging processes for workpieces of different shapes, if there are hundreds of thousands of workpieces, hundreds of thousands of processes need to be compiled, and the operation during production is quite complicated, which requires the operator to determine the processing parameters, and the complex workpieces must be operated by skilled professional technicians. What is more regretful is that this method can only eliminate 23% of workpiece stress and cannot achieve the purpose of processing all workpieces.

Vibration aging stress removal

Vibration aging technology, which is called "Vibrating Stress Relief" (VSR for short) abroad, aims to resonate the processed workpiece through dedicated vibration aging equipment, and through this resonance mode, a certain vibration energy is transmitted to all parts of the workpiece, so that microscopic plastic deformation occurs inside the workpiece-the distorted lattice gradually restores the equilibrium state. Dislocation slip and pin again, finally the residual stress is eliminated and homogenized, thus ensuring the stability of workpiece dimensional accuracy.

The essence of vibration aging is to apply additional dynamic stress to the workpiece in the form of resonance. When the additional dynamic stress and residual stress are superimposed, the yield limit of the material is reached or exceeded, the workpiece undergoes micro or macro plastic deformation, thus reducing the residual stress inside the homogeneous chemical parts and stabilizing its dimensional accuracy.