NEWS

Lift Rod stress classification of materials

Time:2021-04-14 View:

Classification

Normal stress and shear stress

Perpendicular to the same section is called normal stress or normal stress, and tangent to the same section is called shear stress or shear stress. Stress will increase with the increase of external force. For a certain kind of material, the increase of stress is limited. Beyond this limit, the material will be destroyed. For a material, the limit that the stress may reach is called the ultimate stress of the material. The limit magnitude of stress should be determined by the mechanical test of the material. Reduce the measured limit stress appropriately and specify the maximum stress that the material can work safely, which is the allowable stress. If the material is to be used safely, the stress in the service period should be lower than its limit stress, otherwise the material will be damaged during use.

When some materials are working, the external force they receive does not change with time. At this time, the internal stress is unchanged, which is called static stress; There are also some materials, its external force changes periodically with time, and the internal stress also changes periodically with time, which is called alternating stress. The failure of materials under alternating stress is called fatigue failure. Generally, the alternating stress of the material is far less than its strength limit under static load, and damage may occur. In addition, the material will cause local increase of stress due to the change of section size, which is called stress concentration. For well-closed formation brittle materials, stress concentration will greatly reduce the strength of components, which should be paid special attention to in the design of components.

When the object is deformed by force, the degree of deformation at each point in the body is generally different. The mechanical quantity used to describe the degree of deformation at a point is the strain at that point. For this reason, we can go to a unit at this point and compare the changes of unit size and shape before and after deformation.

Unit: Pa,Psi

Tensile stress and compressive stress

If a cylinder is pressed at both ends, the stress along its axis is compressive stress. Compressive stress refers to the stress that makes the object have compression tendency. Not only does the object stress cause compressive stress, but any compression deformation will occur, including after the object expands. In addition, if a beam is bent, whether it is stressed or caused by uneven heating of the beam, etc., the inside of the bending will naturally be stressed, and the outside will be under tensile stress.

In fact, tensile stress represents positive stress and compressive stress represents negative positive stress.

The unit of stress is Pa.

1 Pa=1 N/m2

In actual engineering, the stress value is relatively large, and MPa or GPa is commonly used as the unit.

1 MPa=10^6Pa

1 GPa=10^9Pa

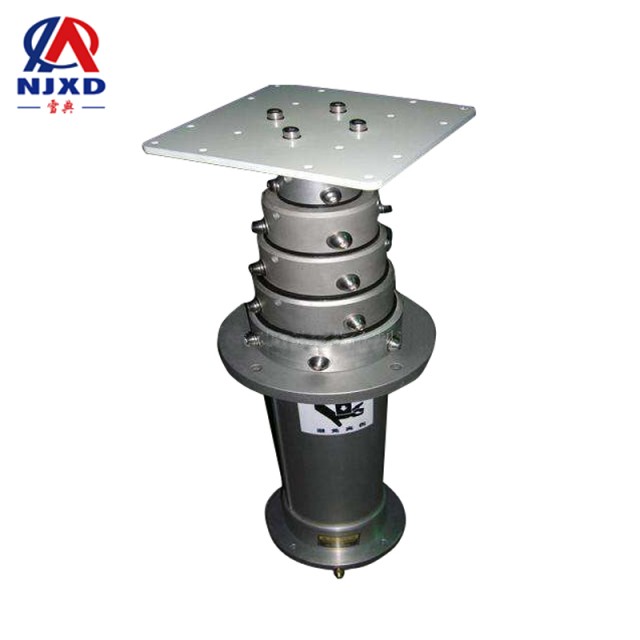

Measuring Tool

Stress meter or strain gauge is an instrument to measure the internal stress of an object. Generally, strain gauges signals are collected and converted into electrical signals for analysis and measurement.

The method is to attach the strain gauges to the measured object so that it can stretch with the strain of the measured object, so that the metal foil inside can stretch or shorten with the strain. The resistance of many metals will change when they mechanically stretch or shorten. Strain gauges applies this principle to measure the strain by measuring the change of resistance. Generally, copper-chromium alloy is used for strain gauges sensitive gates, and its resistance change rate is constant, which is proportional to the strain.

Through the Wheatstone bridge, this proportional relationship of resistance can be converted into voltage. Then different instruments can convert this voltage change into measurable data.

For stress meters or strain gauge, the key indicators include: test accuracy, sampling speed, number of channels supported by the test, dynamic range, and supported strain gauges models. In addition, the software supporting the stress meter is also very important, which requires various functions such as real-time display, real-time analysis, real-time recording, etc. High-end software also has various signal processing capabilities.

In addition, some instruments are designed through the principles of spectrum, diaphragm, etc.