NEWS

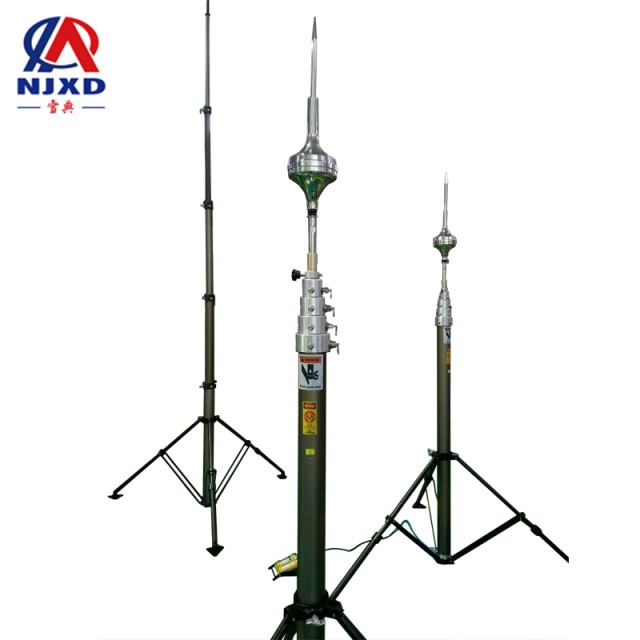

Basic Introduction to down lead ightning Rod telescopic bracket

Time:2021-05-12 View:

A complete set of lightning protection devices includes lightning receiver, down lead and grounding device. Down lead refers to the metal conductor connecting the lightning receiver and the grounding device. The down lead of lightning protection device should meet the requirements of mechanical strength, corrosion resistance and thermal stability.

Introduction

Down lead is a metal conductor that leads Lightning current from the lightning receiver into the grounding device. Installation method, there are special metal wire along the exterior wall of the building; There are metal components of the building (such as fire escape ladder, etc.), metal chimneys, metal ladders of chimneys, etc; there is the use of reinforcement in the concrete in the building. However, no matter what method is used for down lead, it must meet its requirements of thermal stability and mechanical strength to ensure that strong lightning current does not melt through. When using the metal components of the building as down lead, the metal components should be connected into electrical channels to prevent counterattack and fire. Open down lead adopts round steel or flat steel (generally round steel) whose size should not be less than the following values: round steel diameter is 8mm; Flat steel section is 48 mm2; Flat steel thickness is 4mm, if down lead is hidden, its section should Plus-sized by one level.

Down lead regulations

(1) down lead should adopt round steel or flat steel, and round steel should be preferred. The diameter of round steel should not be less than 8mm. The section of flat steel should not be less than 48 mm2, and its thickness should not be less than 4mm. When the following line on the chimney adopts round steel, its diameter should not be less than 12mm; When flat steel is adopted, its cross section should not be less than 100 mm2 and its thickness should not be less than 4mm. The anti-corrosion measures are the same as those of the lightning receiver. The use of steel bars in building components as down lead should meet the requirements of lightning protection measures of Class II and Class III lightning protection buildings.

(2) down lead should be exposed along the exterior wall of the building and grounded through the shortest path. It can be concealed with higher architectural art requirements, but its round steel diameter should not be less than 10mm, flat steel section should not be less than 80 mm2.

(3) metal components such as fire escape ladder and steel column of the building should be used as down lead, but all components should be connected into electrical channels.

(4) when using multiple down leads, breaking of contact should be installed between 0.3~1.8m from the ground on each down lead. When the reinforcement and steel column in concrete are used as natural down lead and the Foundation grounding body is adopted at the same time, no breaking of contact can be set. However, when using steel bar as down lead, several connecting plates should be set up in appropriate places indoors and outdoors, which can be used for measurement, artificial grounding body and equipotential connection. When only the steel bar is used as the down lead and the artificial grounding body buried in the soil is adopted, the grounding body connecting plate should be set on each down lead at least 0.3m from the ground. When using artificial grounding body buried in soil, breaking of contact should be set, and its upper end should be welded with connecting plate or steel column, and there should be obvious marks at the connecting plate.

(5) where it is vulnerable to mechanical damage and personal contact, a section of ground wire from 1.7m on the ground to 0.3m below the ground should take protective measures such as concealed or galvanized steel pipe, modified plastic pipe or rubber hose.

Settings for down lead

Except for the use of steel bars in concrete as down lead. Down lead should be galvanized, and the welding place should be coated with antiseptic paint. In places with strong corrosion, the lead should Plus-sized the cross section or take other anti-corrosion measures.

(1) down lead should be laid along the exterior wall of the building and grounded through the shortest path. Those with higher architectural art requirements can also be concealed, but the section should Plus-sized by one level. Down lead should not be laid near the balcony and the entrance and exit of the building and the place where personnel are more accessible.

(2) according to different lightning protection levels of buildings, the setting of lightning protection down lead is also different. When the first-class lightning protection building is specially set down lead, the number of its roots should not be less than two, and the spacing should not be more than 18 m; The number of the second-class lightning protection building down lead should not be less than two, and the spacing should not be more than 20 m; when the three-level lightning protection building is specially equipped with down lead for lightning protection device, the number of down lead should not be less than two, and the spacing should not be more than 25mm.

Down lead open laying

The down lead must be laid out after straightening. If the material of down lead is flat steel, it can be placed on the flat plate and straightened by Hammer. If down lead is round steel, one end can be fixed on the machine tool of hammer anchor, the other end is fixed on the fixture of grinding or chain inversion, and it can be straightened by cold drawing or bar straightener.

After the straightened down lead material is transported to the installation site, it can be pulled to the highest point of the building with a rope, and it can be Lantern Ring stuck with the support clip buried in the wall from top to bottom, fix with bolts or welding until the clip is broken.

The down lead path is as short and straight as possible. When it is necessary to bend through the roof overboard and other places, it should not constitute an acute angle turning point, and should be made into a slow bending with a larger curve diameter. The total length of the line segment of the curved part should be less than 10 times of the distance at the turning opening. When down lead passes through the overboard and parapet, the method is shown in the figure.

CATEGORY

NEWS

- The installation and protection range of the lightning receiver is up and down ightning rod

- Basic Introduction to down lead ightning Rod telescopic bracket

- Grounding device classification ightning rod lift rod

- Installation of grounding device ightning Rod telescopic rod

- Lightning protection device introduction ightning Rod lifting bracket