NEWS

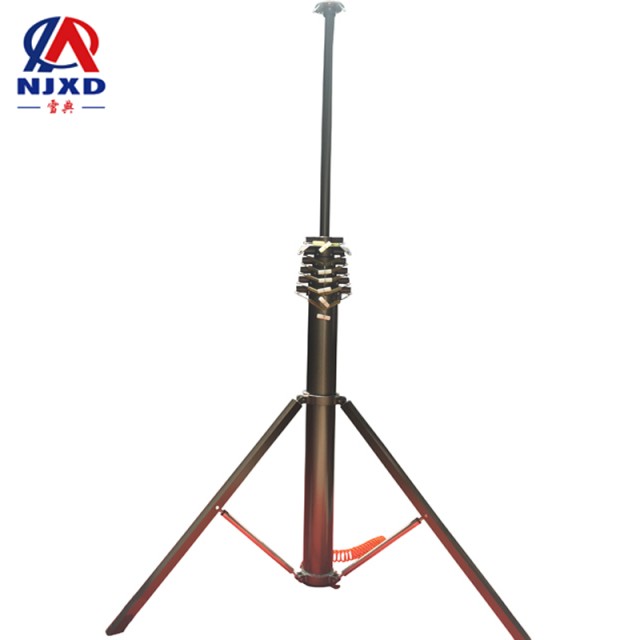

Mechanical seal type pneumatic telescopic bracket

Time:2021-09-03 View:

Product Type

HU1

Structural features

HU1 mechanical seal conforms to ISO3096DIN24960 and GB6556 standards. The auxiliary sealing coil can use rubber "O" ring PTFE "V" ring of the same specification according to the working condition requirements. Single spring and unbalanced fork have strong transmission and compensation capability, and have nothing to do with shaft rotation during installation.

Friction pair material and auxiliary sealing material can be selected according to actual working conditions. It can be used in telescopic mast.

Scope of Application

Sealed medium: oil-water, crystalline strong alkali, salt, high solubility fluid, slurry, organic solvent and other weak corrosion solutions.

Seal cage pressure: ≤ 1Mpa

Seal cage temperature:-20 ℃ to 220 ℃

Linear speed: ≤ 15m/s

HU3 type

Structural features:

HU3 mechanical seal conforms to DIN24960 and GB/T6556-94 standards, and can replace 116U and 59U mechanical seals, non-balanced, single-end structure, and arbitrary rotation. All kinds of sewage pump, chemical pumps and thermal circulating pump are applicable. Spring selection: Butterfly Spring, multi-Spring, etc.

Friction pair material and auxiliary sealing material should be selected according to actual working conditions.

Scope of Application:

Sealed medium: oil, water, acid, alkali, salt and other general corrosive medium.

Seal cage pressure: ≤ 1.6mpa

Seal cage temperature:-50 ℃ to 220 ℃

Linear speed: ≤ 20 m/s

HU5 type

Structural features:

HU5 type mechanical seal meets the DIN24960 standard, and Kappa installation also meets the DIN24960 standard double side mechanical seal, which is partially balanced, rubber bellows, single spring, single end structure, the moving ring is driven by the interference of rubber bellows, which has good floating performance, and the spring also transmits torque.

Friction pair material and auxiliary sealing material should be selected according to actual working conditions.

Scope of Application:

Sealed medium: waste water, oil and sewage containing particles.

Seal cage pressure: ≤ 1.6Mpa

Seal cage temperature:-20 ℃ to 140 ℃

Linear speed: ≤ 10 m/s

HU7 type

Structural features:

HU7 mechanical seal conforms to DIN24960 and GB/T6556-94 standards and can replace 108U mechanical seal. It has non-balanced and conical spring structure. The rotation direction of the spring is related to the axial rotation direction.

Friction pair material and auxiliary sealing material can be selected according to actual working conditions.

Scope of Application:

Sealed medium: sewage pump, submersible pump, chemical pump, circulating pump, clean water pump and heating system.

Seal cage pressure: ≤ 1Mpa

Seal cage temperature:-20 ℃ to 180 ℃

Linear speed: ≤ 15m/s

HUU803

Structural features:

HUU803 mechanical seal conforms to DIN24960 and GB/T6556-94 standards, is non-balanced, multi-spring structure double side, drive sleeve transmission. Seal cage pressure must be 0.1-0.2Mpa higher than medium pressure.

Friction pair material and auxiliary sealing material should be selected according to actual working conditions.

Scope of Application:

Sealed medium: acid, alkali, salt, seawater, vapor flammable and explosive toxic medium

Seal cage pressure: ≤ 1.6Mpa

Seal cage temperature:-50 ℃ to 150 ℃

Linear speed: ≤ 20 m/s

HBM1 type

Structural features:

HBM1 mechanical seal meets the DIN24960 standard and is a single-end, balanced, arbitrary rotating metal bellow type seal. Moving ring O-ring and flexible graphite ring do not have compensation effect, so there is no resistance to bellows movement, which is suitable for high temperature, high viscosity medium.

Friction pair material and auxiliary sealing material should be selected according to actual working conditions.

Scope of Application:

Sealed medium: oil, acid, alkali and other general corrosive liquid.

Seal cage pressure: ≤ 2.5Mpa when Bellows is under external pressure

≤ 1.5Mpa when Bellows is under internal pressure

Seal cage temperature:-20 ℃ to 400 ℃

Linear speed: ≤ 15m/s

HBM5 type

Structural features:

HBM5 type mechanical seal is a single-end, balanced and rotary metal bellows mechanical seal. The moving ring part is connected with the shaft sleeve as a whole. The whole set of mechanical seal is assembled, simplifying the installation process and adjusting outside the pump, this makes it easier to install mechanical seals. It is widely used in chemical industry, paper making, sewage and other industries.

Friction pair material and auxiliary sealing material should be selected according to actual working conditions.

Scope of Application:

Sealed medium: oil, water, sewage, weak acid, weak alkali and solution containing a small amount of microparticles, etc.

Seal cage pressure: ≤ 2Mpa

Seal cage temperature:-30 ℃ to 200 ℃

Linear speed: ≤ 25 m/s

HQ901

Structural features:

HQ901 mechanical seal belongs to external type, single end face, multi-Spring, static type, balanced type structure, spring does not contact with medium, axial size is short. It can replace framework oil seal, assemble design, simplify installation process, and make installation easier and more convenient.

Friction pair material and auxiliary sealing material should be selected according to actual working conditions.

Scope of Application:

Sealed medium: oil, water and other liquids.

Seal cage pressure: ≤ 1.6Mpa

Seal cage temperature:-20 ℃ to 160 ℃

Linear speed: ≤ 20 m/s

HQ902

Structural features:

HQ902 mechanical seals are single-face, balanced, multi-spring and static mechanical seals. The spring does not contact with the medium, and the assembly design makes the installation easier.

Friction pair material and auxiliary sealing material should be selected according to actual working conditions.

Scope of Application:

Sealed medium: oil, water, sewage, acid and alkali solution.

Seal cage pressure: ≤ 1.6Mpa

Seal cage temperature:-20 ℃ to 160 ℃

Linear speed: ≤ 20 m/s

HG9 type

Structural features:

HG9 type mechanical seal belongs to single end face, non-balanced rubber bellows structure, HG9 type mechanical seal its G60 conforms to DIN24960 standard, G50 conforms to European standard, G55 conforms to American standard, its floating adjustment performance is good, it can enhance or reduce the number of springs to meet the requirements of axial installation. It has simple structure, convenient installation and good working performance. It is recognized by international authoritative pump factories and is very popular with users.

Friction pair material and auxiliary sealing material should be selected according to actual working conditions.

Scope of Application:

Sealed medium: cold water, hot water, beverage, weak acid and weak alkali, various media containing particulate matter.

Seal cage pressure: ≤ 0.8Mpa

Seal cage temperature:-20 ℃ to 140 ℃

Linear speed: ≤ 10 m/s

HU21

Structural features:

HU21 mechanical seal is mainly faced with harsh media under various working conditions such as pipeline pump, sewage pump, clean water pump, and submersible pump. Its installation size is short and balancing factor high, which can replace various light mechanical seals: crane 502, 2100, Bogman MG1, domestic 109,BIA, FBD and other mechanical seals. Its transmission relies on rubber to drive cards and fork to drive, effectively avoiding the failure and aging speed of rubber bellows.

Scope of Application:

Sealed medium: oil, water, and other general corrosive liquid.

Seal cage pressure: ≤ 0.6Mpa

Seal cage temperature:-40 ℃ to 120 ℃

Linear speed: ≤ 15m/s

HQ3272

Structural features:

HQ3272 mechanical seal is mainly used for various imported multistage pump and various water treatment conditions. Its tight design and short appearance size make it available in any working condition, and it is easy to install and operate.

Scope of Application:

Sealed medium: oil, water, sewage, acid and alkali solution.

Seal cage pressure: ≤ 1.6Mpa

Seal cage temperature:-20 ℃ to 160 ℃

Linear speed: ≤ 20 m/s

Others

Floating seal (mechanical face seal)

Floating seal is mainly used in construction machinery and mining machinery to effectively prevent the damage of dust, sand and mud to equipment and prevent the invasion of destructive media.

Scope of Application: severe working conditions of wear media such as dust, sand, mud, rock or soil

Seal cage pressure: ≤ 0.3Mpa

Linear speed: ≤ 10 m/s