NEWS

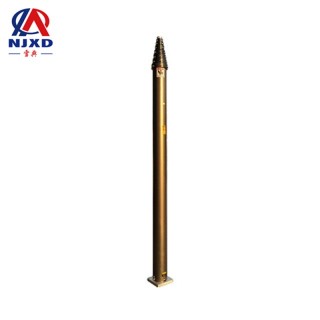

Selection of pneumatic multi-section cylinder lifting mast and hard oxidation technology

Time:2020-09-17 View:

How to select the type of pneumatic lifting rod, namely, multi-section cylinder, in Xuedian NJXD

The general process of the selection of pneumatic lifting rod/multi-section cylinder is as follows: First of all, calculate the piston area F = n * P * S of the cylinder according to the output you need, in the formula, F is the required output Force, P is the system pressure, S is the piston area, and n is the safety factor. Generally, 0.7 is taken for horizontal use of the cylinder, 0.5 is taken for straight use, when the piston area comes out, it is converted into the diameter of the piston, which is usually indicated by the diameter of the cylinder. The second is to select the accurate stroke according to the movement interval of pneumatic lifting rod/multi-section cylinder. If the demand is tight, it will usually eat 3~5mm. Then select the device you need according to the device method, which is the angle seat, and the flange is still the earring device. Finally, it is good to choose whether it is required, travel check switch and other accessories.

It can be seen that the main data of the selection of pneumatic lifting rod/multi-section cylinder is the cylinder diameter and stroke. The detailed methods and processes are discussed as follows:

● The cylinder diameter scale of the selected cylinder

According to the requirements of the thrust tension of the cylinder, select the pressure parameters and cylinder diameter scale for the cylinder.

Calculation Formula of cylinder thrust: cylinder thrust F1 = 0.25 ÷ d2p

Calculation Formula of cylinder tension: F2 = 0.25π(D2-d2)P

In the formula: D-cylinder piston diameter (cm)

d-cylinder piston rod diameter (cm)

P-working pressure of cylinder (kgf/cm2)

F1,F2-theoretical pushing force of cylinder (kgf)

The above output calculation is applicable to the speed range of pneumatic lifting rod/multi-section cylinder of 50~500 mm/s.

When using the straight method device above the cylinder, the upward thrust is about 50% of the theoretical calculation thrust;

When the cylinder is applied horizontally, consider the inertia elements, and the practical output is basically equal to the theoretical output.

● Select the movement stroke of the cylinder: determine the movement interval of the work, and consider the working condition to select the full stroke or the reserved stroke. When the stroke exceeds the recommended longest stroke, consider the stiffness of the piston rod, and be able to select support guide or special cylinder.

● buffer method of selected cylinder: Select buffer method according to requirements, no buffer cylinder, fixed buffer cylinder, adjustable buffer cylinder

● The smooth method of selecting the cylinder: there is a smooth cylinder with oil supply, but there is no smooth cylinder with oil supply

● select the type series of cylinders: select the appropriate type series of cylinders according to the above conditions

● device method for selecting cylinder: select appropriate device method according to different uses and device requirements. The installation methods include: Basic type, foot seat type, Rod side flange type, non-rod side flange type, single earring type, double ear ring type, Rod side ear shaft type, non-rod side ear shaft type, center ear shaft type.

● relevant accessories for selecting cylinder: front (rear) flange, tripod, single (double) suspension ear, middle hinge shaft type, hinge shaft support type

The above is the method and process of how to select the pneumatic lifting rod/multi-section cylinder, hoping to help us when selecting the cylinder.

I. Brief introduction of hard oxidation technology of pneumatic lifting rod

The pneumatic lifting rod produced by NJXD technology uses hard anodic oxidation technology, which is a thick film anodic oxidation method, according to the special anodic oxidation surface treatment technology of aluminum and aluminum alloy. Through this technology, the maximum thickness of the prepared anodic oxide film can reach about 250 microns, and the microhardness oxide film of 1500kg/mm2 can be obtained on pure aluminum, however, the microhardness oxide film of 400~600kg/mm2 can be obtained on aluminum alloy.

The oxide film layer thermal conductivity is poor, its melting point is 2050 ℃, the resistance coefficient is larger, the shutdown processing (immersed insulation or white wax) breakdown voltage up to 2000V in the atmosphere higher corrosion resistance, it has high abrasion resistance, is also an aspiring thermal insulation film layer, also has outstanding insulation, and has a series of advantages such as strong connection with matrix metal, therefore, it has been widely used in the national defense industry and the machinery parts manufacturing industry.

II. Application fields

Hard anodic oxidation technology is mainly applied to aluminum and aluminum alloy parts that require high wear resistance, heat resistance and good insulation performance, except for the pneumatic lifting rod used to make aluminum alloy raw materials. Such as various inner walls as cylinders, Pistons, steam plugs, cylinders, bearings, floors of aircraft cargo compartments, rolling rods and guide rails, water conservancy equipment, steam impellers, leveling machines, gear, cushion and other parts.

III. Analysis of advantages and disadvantages

(1) advantages: using hard oxidation technology to make pneumatic lifting rod to replace traditional hard chromium plating, compared with hard chromium technology, it has the advantages of low cost, strong connection of film layer, convenient treatment of plating solution and cleaning waste liquid, etc.

② defect: the defect of the film obtained by this technology is that when the thickness of the film is large, it will affect the mechanical fatigue strength target of aluminum and aluminum alloy.

IV. Oxidation methods

There are many hard anodic oxidation electrolysis methods used when making pneumatic lifting rod of aluminum alloy, such as sulfuric acid, oxalic acid, propylene glycol, sulfosalicylate and other inorganic salts and organic acids. The power supply used can be divided into DC, AC and AC/DC superimposed power supply, etc. At present, the following two kinds of hard anodic oxidation technologies are widely used in the pneumatic lifting rod processing industry.

(1) sulfuric acid hard anodic oxidation DC method;

(2) oxalic acid hard anodic oxidation AC/DC reselection method.

In the meantime, sulfuric acid method is a kind of hard anodic oxidation technology which is widely used now.

V. Summary

Generally speaking, hard anodic oxidation technology is the best surface treatment technology for manufacturing aluminum alloy pneumatic lifting rod. Through this technology, the oxide film formed on the surface of the pneumatic lifting rod has strong ability to resist chemical corrosion and physical conflict, which makes the rod body have high abrasion resistance. In addition, due to the poor thermal conductivity and electrical conductivity of the oxide film, it becomes the desired thermal insulation film layer of the pneumatic lifting rod and has outstanding insulation. Hard anodic oxidation technology not only enhances the beauty and safety of pneumatic lifting rod products, but also extends the service life of pneumatic lifting rod to a great extent.

CATEGORY

NEWS

- Application of production process of pneumatic lifting rod in Mobile Command Vehicle

- Selection of pneumatic multi-section cylinder lifting mast and hard oxidation technology

- General-purpose pneumatic lifting mast for mobile emergency lighting vehicle

- Procurement and application of modified pneumatic Rod for police lifting lighting monitoring

- How to carry electric lifting lightning arrester equipment and how to maintain it